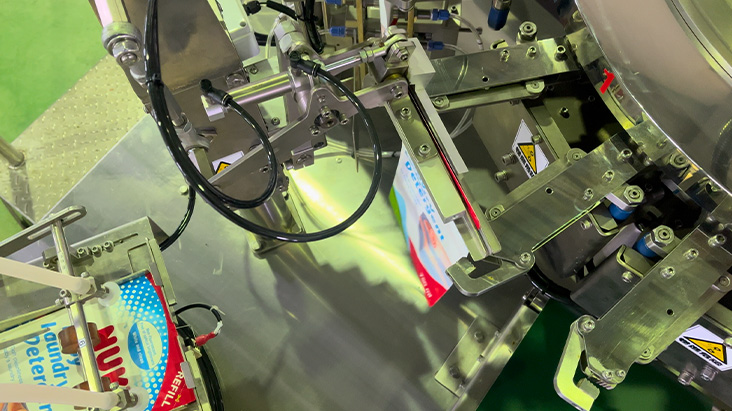

Advantage

Bearing Packaging Exclusive

Capacity:Up To 20 CPM

Intermittent - Motion Packaging

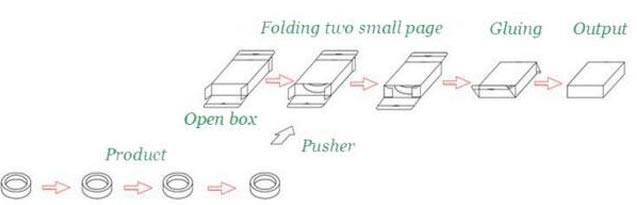

Flowchart

Product Key Features & Advantages

- Automatic Carton Forming and Sealing with Pneumatic Cylinders

Uses pneumatic cylinders to automatically erect, form, and mechanically seal cartons via tuck-in flaps. The simplified structure ensures high stability, easy maintenance, and excellent repeatable accuracy. - High-Speed, Reliable Performance for Mass Production

Achieves packaging speeds of 15+ CPM with outstanding stability and low downtime—perfect for meeting mass production needs. - Adjustable Speed with HMI

Equipped with an HMI, the machine allows real-time motor speed adjustments during operation—enabling flexible responses to different bearing specifications and production requirements. - High-Efficiency, Low-Noise Design

Powered by a precision gear system that enhances performance and minimizes noise, ensuring a smooth and quiet production environment. - Modular Design for Quick Changeovers

The fully modular system enables fast manual adjustments to fit various bearing sizes, ensuring production flexibility and responsiveness. - Smart Detection, Auto Rejection

Photoelectric and vision sensors inspect each carton in real time. Any missing bearing is instantly rejected to ensure consistent quality. - Highly scalable, supports full-line automation

Capable of integrating with Our Wrap-iQ®:YH WQ-B25 Film Folding Overwrapping Machine and downstream equipment to achieve a fully automated, integrated workflow of Shrink film wrapping → Cartoning → Inspection → Packaging, enabling a highly efficient full-line solution.