Advantage

Bearing Packaging Exclusive

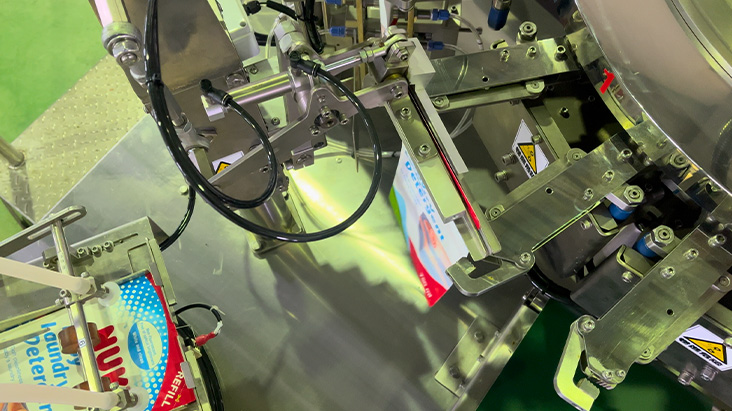

Capacity:Up To 20 CPM

Product Features

- Smart, Damage-Free Cartoning

Inspired by the elegance of traditional furoshiki wrapping, our advanced packaging system uses finely tuned mechanical movements and a precise folding method to securely cushion and protect each bearing. By minimizing friction between the product and packaging material, it ensures a smooth, damage-free experience—every time. - Highly Compatible Design

Equipped with adjustable molds, the system allows quick and easy switching between various bearing sizes. It supports heat-activated films with adhesive and shrinkable properties—such as OPP/CPP composite films—and integrates seamlessly with automated systems to ensure consistent and reliable packaging results. - Industrial-Grade Protective Packaging

With film folding and overwrapping combined with a tightly sealed structure, the packaging effectively prevents dust intrusion and protects against vibration damage during transportation—all while showcasing a premium industrial look and feel. - Professional Visual Presentation

Designed with clean geometric folding, the packaging forms a sharp and cohesive outline that reinforces brand identity. It meets the high standards of export markets for visual consistency and a professional image. - Efficiency Meets Protection

By replacing traditional manual work with automated packaging, the system boosts efficiency by 2 to 4 times while significantly reducing the risk of bearing damage during the packaging process. - Customizable Material Flexibility

Available in a variety of material options—including food-grade stainless steel (SUS304)—the system adapts to different budget levels and protection requirements, helping businesses optimize cost management.